OKUMA Data Access

To access the data, special addresses are used by HumanOS to index the memory for reading or writing.

Addressing the Memory

The address is built with five numbers:

{SubSystem}:{MajorIndex}:{SubScript}:{MinorIndex}:{Style}

These parameters correlate one by one to the API of OKUMA.

SubSystem Index

The SubSystem index differs between the machine types. Whenever an address description denotes {SubSystem}

checks the following tables to select the correct SubSystem.

SubSystem Index for Machining Centers

| SubSystem | Description | MachineType |

|---|---|---|

| 0 | Machining centers | MachiningCenter and MachiningCenterV2 |

| 14 | Common for Machine Centers and Lathes | MachiningCenter, MachiningCenterV2 and Lathe |

SubSystem Index for Lathe

| SubSystem | Description | MachineType |

|---|---|---|

| 0 | Panel selection machine/panel selection turret/command selection spindle | Lathe |

| 5 | Panel selection machine/first turret (side A)/command selection spindle | Lathe |

| 6 | Panel selection machine/second turret (side B)/command selection spindle | Lathe |

| 7 | Panel selection machine/third turret (side C)/command selection spindle | Lathe |

| 8 | MTB | Lathe |

| 14 | Common to L/M | MachiningCenter, MachiningCenterV2 and Lathe |

| 16 | NC loader (panel selection system) | Lathe |

| 17 | NC loader (first system) | Lathe |

| 18 | NC loader (second system) | Lathe |

| 19 | Panel selection machine/panel selection turret/panel selection spindle | Lathe |

| 20 | Panel selection machine/first turret (side A)/panel selection spindle | Lathe |

| 21 | Panel selection machine/second turret (side B)/panel selection spindle | Lathe |

| 22 | First machine/first turret (side A)/first spindle (Side A of 1S and 2S lathes, R spindle of parallel 2SP machine)" | Lathe |

| 23 | First machine/first turret (side A)/second spindle (Second spindle of 1S lathe, second spindle on side A of 2S lathe) | Lathe |

| 24 | First machine/second turret (side B)/first spindle (Side B of 2S lathe)" | Lathe |

| 25 | First machine/second turret (side B)/second spindle (Second spindle on side B of 2S lathe)" | Lathe |

| 26 | Second machine/first turret (side A)/first spindle ( L spindle of parallel 2SP machine)" | Lathe |

| 27 | Second machine/first turret (side A)/second spindle | Lathe |

| 28 | First machine/Third turret (side C)/first spindle | Lathe |

| 29 | First machine/Third turret (side C)/second spindle | Lathe |

SubSystem Index for Grinder

| SubSystem | Description | MachineType |

|---|---|---|

| 0 | Panel selection machine / panel selection wheel head / command selection spindle | Grinder |

| 2 | PLC | Grinder |

| 5 | Panel selection machine / first wheel head / command selection spindle | Grinder |

| 8 | MTB | Grinder |

| 14 | Common to L/M/G | Grinder, Lathe, MachiningCenter, MachiningCenterV2 |

| 16 | NC loader (panel selection system) | Grinder |

| 17 | NC loader (first system) | Grinder |

| 19 | Panel selection machine / panel selection wheel head / panel selection spindle | Grinder |

| 20 | Panel selection machine / first wheel head / panel selection spindle | Grinder |

| 22 | First machine / first wheel head / first spindle | Grinder |

| 23 | First machine / first wheel head / second spindle | Grinder |

System Variables

| Address | Description | Data Type |

|---|---|---|

0:0:0:0:0 | Available flag. 0 = Connection offline, 1 = online | System.Boolean |

0:0:0:0:1 | Signal of Life; Alternates in 1 Hz if connection is online | System.Int32 |

Program Information

Machining Center

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

14:1001:0:0:8 | Operation mode. (0=AUTO; 1=MDI; 2=MANUAL) | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

14:1004:0:0:8 | Get either of Running(1) or Not running(0) as the program status. | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

14:5010:0:0:0 | Get the selected main program file name. | System.String | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

0:5035:0:0:0 | Get O number (main program name, execution program name) after the program has been selected. | System.String | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

14:5014:0:0:0 | Get the currently executed sequence No. (name) | System.String | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

14:5003:0:0:0 | Get the alarm message, which is a character string of 64 digits at maximum. | System.String | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

14:3905:0:0:8 | Get the block number. Currently executed. | System.Int32 | MachiningCenter | >= 3.0.0 | [X] P200M [O] P300M/S(MP) |

14:1:0:0:8 | Alarm Status (0= no alarm; 1 = alarm) | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

14:1:0:2:8 | NC on hold (0= no hold; 1 = hold) | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

14:1:0:4:8 | NC running (0= not running; 1 = running) | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

14:1:0:5:8 | Program stop (0= not stopped; 1 = stopped) | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

14:1:0:6:8 | Turret Selection status | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

Lathe

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

{SubSystem}:1004:0:0:8 | Operation mode. (-128=AUTO; 64=MDI; 32=MANUAL) | System.Int32 | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:1901:0:0:8 | Get either of Running(1) or Not running(0) as the program status. | System.Int32 | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:5001:0:0:0 | Get the program no. (name) currently executed. | System.String | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:5004:0:0:0 | Get the main program file name currently selected. | System.String | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:5014:0:0:0 | Get the currently executed sequence No. (name) | System.String | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:5009:0:0:0 | Get the alarm message. It is a character string of 64-digit at maximum. | System.String | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:19:0:0:8 | Alarm Status (0= no alarm; 1 = alarm) | System.Int32 | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:19:0:2:8 | NC on hold (0= no hold; 1 = hold) | System.Int32 | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:19:0:4:8 | NC running (0= not running; 1 = running) | System.Int32 | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:19:0:5:8 | Program stop (0= not stopped; 1 = stopped) | System.Int32 | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:19:0:6:8 | Turret Selection status | System.Int32 | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

SubSystem: Designating SubSystem = 0, 5 to 7, 19 to 29 for lathe is possible. Designate a value between 22 to 26, 28, 29 in general.

Grinding

| Address | Description | Data Type | MachineType | Version |

|---|---|---|---|---|

{SubSystem}:1004:0:0:8 | Operation mode. (-128=AUTO; 64=MDI; 32=MANUAL) | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:1901:0:0:8 | Get either of Running(1) or Not running(0) as the program status. | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:5001:0:0:0 | Get the program no. (name) currently executed. | System.String | Grinder | >= 3.0.0 |

{SubSystem}:5002:0:0:0 | Get the sequence number or name currently executed. | System.String | Grinder | >= 3.0.0 |

{SubSystem}:3052:0:0:8 | Get the block number. Currently executed. | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:5004:0:0:0 | Get the main program file name currently selected. | System.String | Grinder | >= 3.0.0 |

{SubSystem}:5009:0:0:0 | Get the alarm message. It is a character string of 64-digit at maximum. | System.String | Grinder | >= 3.0.0 |

{SubSystem}:19:0:0:8 | Alarm Status (0= no alarm; 1 = alarm) | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:19:0:2:8 | NC on hold (0= no hold; 1 = hold) | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:19:0:4:8 | NC running (0= not running; 1 = running) | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:19:0:5:8 | Program stop (0= not stopped; 1 = stopped) | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:19:0:6:8 | Turret Selection status | System.Int32 | Grinder | >= 3.0.0 |

SubSystem: Designating SubSystem = 0, 5, 19, 20, 22, 23 for grinder is possible. Designate a value between 22, 23 in general.

Feed Override and Speeds

Machining Center

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

0:2017:0:0:8 | Rapid Override in % | System.Int32 | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

0:2018:0:0:8 | Feedrate Override in % | System.Int32 | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

0:3018:0:0:2 | Get the actual feed rate (mm/min). | System.Int32 | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

0:3019:0:0:2 | Get the actual feed rate (mm/rev). | System.Int32 | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

0:3098:0:0:2 | Get the F command value on "BLOCK DATA" screen. | System.Int32 | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

Lathe

Not available.

Grinder

| Address | Description | Data Type | MachineType | Version |

|---|---|---|---|---|

{SubSystem}:2942:0:0:8 | Get the state of Wheel override switch (%). | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:2944:0:0:8 | Get the state of Feed Axis override switch (%). | System.Int32 | Grinder | >= 3.0.0 |

SubSystem: Designating SubSystem = 0, 5, 19, 20, 22, 23 for grinder is possible. Designate a value between 22, 23 in general.

Workpiece Counter

The work counter is a value between 0 and 99999999.

Machining Center

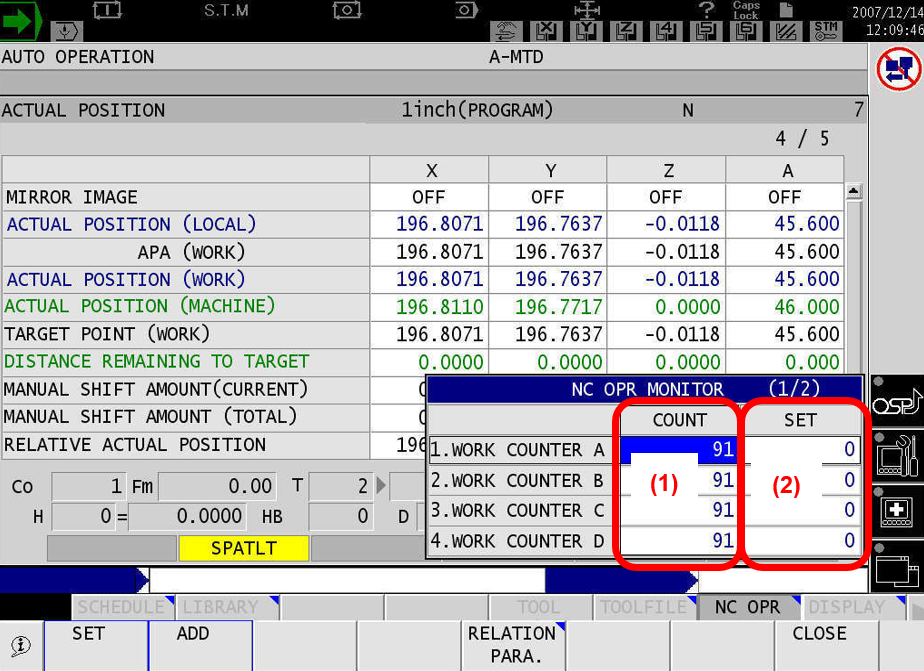

NC OPR MONITOR (1/2)

NC OPR MONITOR (1/2)

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

0:3066:{row}:0:8 | Read or write the workpiece counter (Counted Value). {row} is in range 0 to 3 | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

0:3067:{row}:0:8 | Read or write the workpiece counter (Set Value). {row} is in range 0 to 3 | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

Lathe

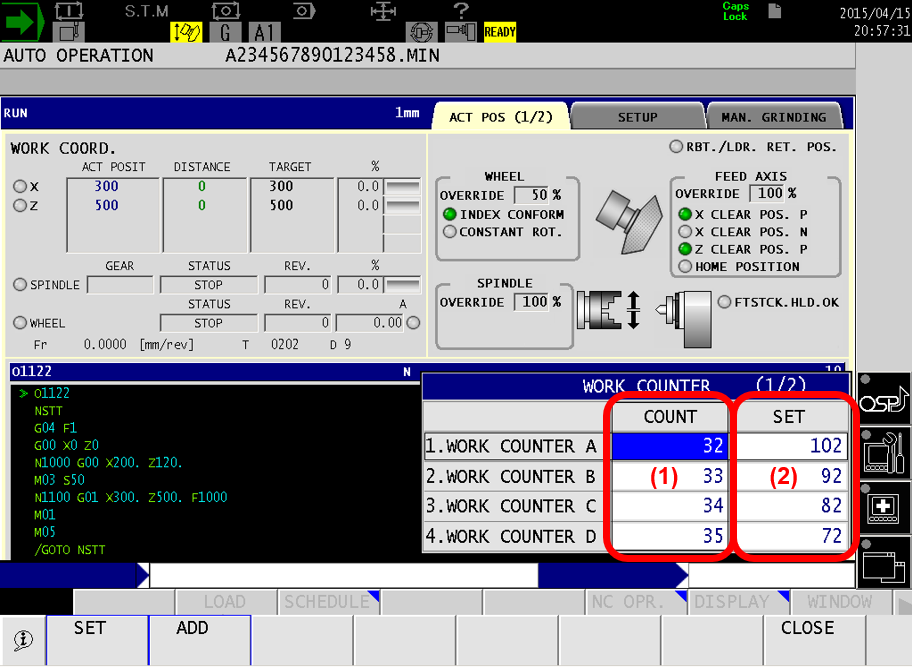

WORK COUNTER(1/2) screen

WORK COUNTER(1/2) screen

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

{SubSystem}:3056:{row}:0:8 | Read or write the workpiece counter (Counted Value). {row} is in range 0 to 3 | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:3057:{row}:0:8 | Read or write the workpiece counter (Set Value). {row} is in range 0 to 3 | System.Int32 | MachiningCenter | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

SubSystem: Designating SubSystem = 0, 5 to 7, 19 to 29 for lathe is possible. Designate a value between 22 to 26, 28, 29 in general.

Grinder

WORK COUNTER(1/2) screen

WORK COUNTER(1/2) screen

| Address | Description | Data Type | MachineType | Version |

|---|---|---|---|---|

{SubSystem}:3056:{row}:0:8 | Read or write the workpiece counter (Counted Value). {row} is in range 0 to 3 | System.Int32 | MachiningCenter | >= 3.0.0 |

{SubSystem}:3057:{row}:0:8 | Read or write the workpiece counter (Set Value). {row} is in range 0 to 3 | System.Int32 | MachiningCenter | >= 3.0.0 |

SubSystem: Designating SubSystem = 0, 5, 19, 20, 22, 23 for grinder is possible. Designate a value between 22, 23 in general.

Operation Timers

Machining Center

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

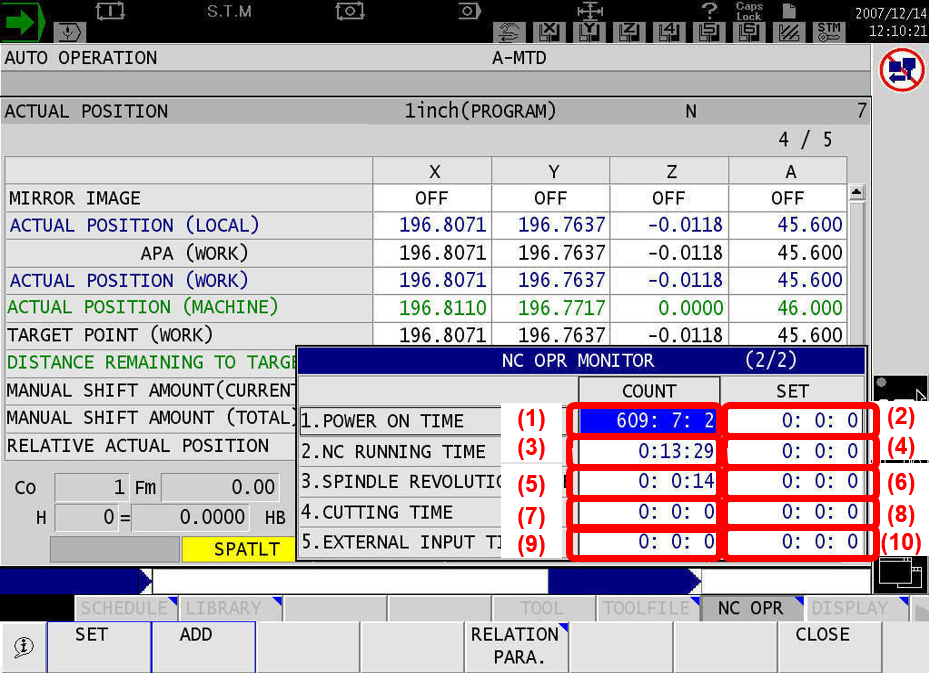

0:{MajorIndex}:0:0:12 | Read or write the operation timers (Counted or set value). For {MajorIndex} see table below. | System.String | MachiningCenter | >= 2.0.0 | [O] P200M [O] P300M/S(MP) |

The string size is max. 12 characters. The value is given as time span 0:0:0 to 99999:59:59

Following table shows the possible {Major} indexes:

| MajorIndex | Description |

|---|---|

| 3056 | Power-ON time [Counted value] (Fig. cell 1) |

| 3057 | Power-ON time [Set value] (Fig. cell 2) |

| 3058 | NC running time [Counted value] (Fig. cell 3) |

| 3059 | NC running time [Set value] (Fig. cell 4) |

| 3060 | Spindle rotation time [Counted value] (Fig. cell 5) |

| 3061 | Spindle rotation time [Set value] (Fig. cell 6) |

| 3062 | Cutting time [Counted value] (Fig. cell 7) |

| 3063 | Cutting time [Set value] (Fig. cell 8) |

| 3064 | External input time [Counted value] (Fig. cell 9) |

| 3065 | External input time [Set value] (Fig. cell 10) |

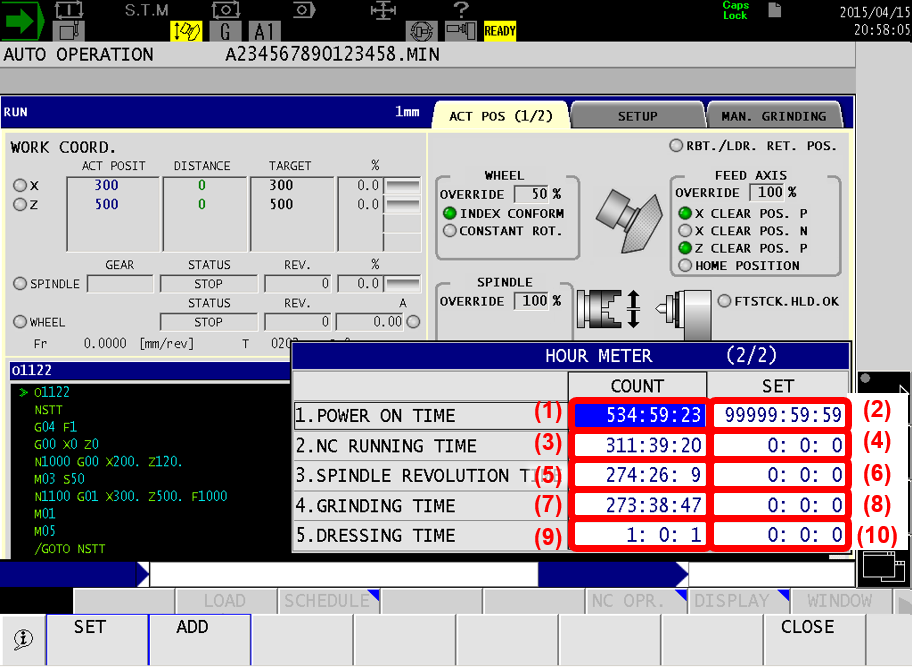

NC OPR MONITOR (2/2)

NC OPR MONITOR (2/2)

Lathe

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

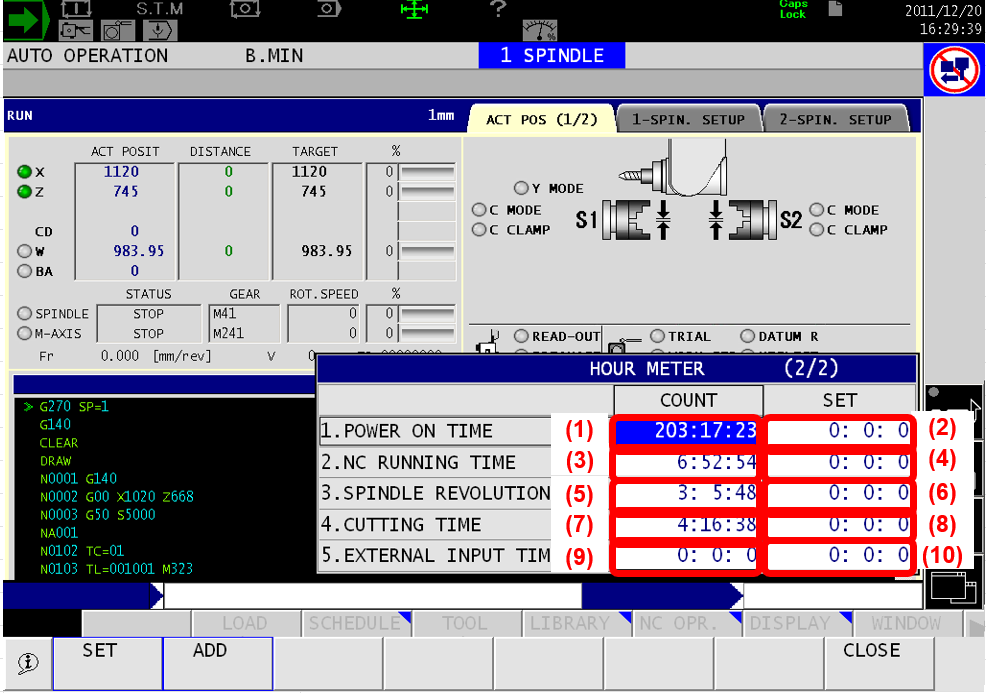

{SubSystem}:{MajorIndex}:0:0:12 | Read or write the operation timers (Counted or set value). For {MajorIndex} see table below. | System.String | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

SubSystem: Designating SubSystem = 0, 5 to 7, 19 to 29 for lathe is possible. Designate a value between 22 to 26, 28, 29 in general.

The string size is max. 12 characters. The value is given as time span 0:0:0 to 99999:59:59

Following table shows the possible {Major} indexes:

| MajorIndex | Description |

|---|---|

| 3058 | Power-ON time [Counted value] (Fig. cell 1) |

| 3059 | Power-ON time [Set value] (Fig. cell 2) |

| 3060 | NC running time [Counted value] (Fig. cell 3) |

| 3061 | NC running time [Set value] (Fig. cell 4) |

| 3062 | Spindle rotation time [Counted value] (Fig. cell 5) |

| 3063 | Spindle rotation time [Set value] (Fig. cell 6) |

| 3064 | Cutting time [Counted value] (Fig. cell 7) |

| 3065 | Cutting time [Set value] (Fig. cell 8) |

| 3066 | External input time [Counted value] (Fig. cell 9) |

| 3067 | External input time [Set value] (Fig. cell 10) |

HOUR METER(2/2) screen

HOUR METER(2/2) screen

Grinder

| Address | Description | DataType | MachineType | Version |

|---|---|---|---|---|

{SubSystem}:{MajorIndex}:0:0:12 | Read or write the operation timers (Counted or set value). For {MajorIndex} see table below. | System.String | Grinder | >= 3.0.0 |

SubSystem: Designating SubSystem = 0, 5, 19, 20, 22, 23 for grinder is possible. Designate a value between 22, 23 in general.

The string size is max. 12 characters. The value is given as time span 0:0:0 to 99999:59:59

Following table shows the possible {Major} indexes:

| MajorIndex | Description |

|---|---|

| 3058 | Power-ON time [Counted value] (Fig. cell 1) |

| 3059 | Power-ON time [Set value] (Fig. cell 2) |

| 3060 | NC running time [Counted value] (Fig. cell 3) |

| 3061 | NC running time [Set value] (Fig. cell 4) |

| 3062 | Spindle rotation time [Counted value] (Fig. cell 5) |

| 3063 | Spindle rotation time [Set value] (Fig. cell 6) |

| 3064 | Grinding time [Counted value] (Fig. cell 7) |

| 3065 | Grinding time [Set value] (Fig. cell 8) |

| 13026 | Dressing time [Counted value] (Fig. cell 9) |

| 13027 | Dressing time [Set value] (Fig. cell 10) |

HOUR METER(2/2) screen

HOUR METER(2/2) screen

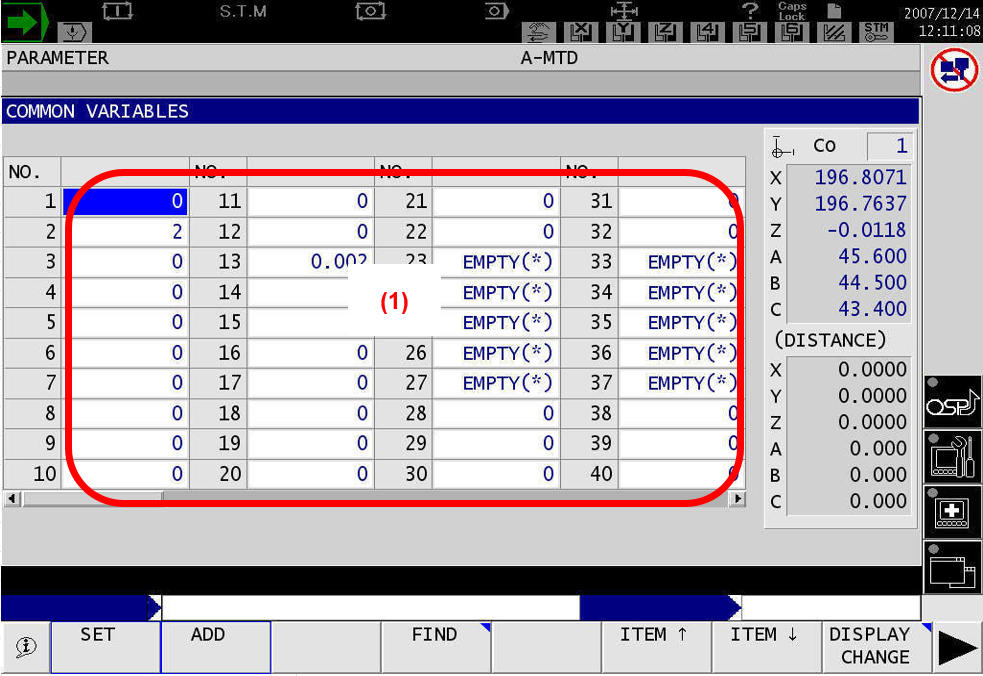

Common Variables

Machining Center

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

0:4001:{number-1}:0:14 | Read or write common variables. {number-1} is the index of the common variable | System.Double | MachiningCenter | >= 1.1.0 | [O] P200M [O] P300M/S(MP) |

NOTE: Use NaN to write an empty value to the NC memory.

NC OPR MONITOR (2/2)

NC OPR MONITOR (2/2)

Lathe

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

{SubSystem}:4001:{number-1}:0:2 | Read or write common variables. {number-1} is the index of the common variable | System.Double | Lathe | >= 1.1.0 | [O] P200L [O] P300L [O] P300S(LP) |

SubSystem: Designating SubSystem = 0, 5 to 7, 19 to 29 for lathe is possible. Designate a value between 22 to 26, 28, 29 in general.

Grinder

| Address | Description | Data Type | MachineType | Version |

|---|---|---|---|---|

{SubSystem}:4001:{number-1}:0:2 | Read or write common variables. {number-1} is the index of the common variable | System.Double | Grinder | >= 3.0.0 |

SubSystem: Designating SubSystem = 0, 5, 19, 20, 22, 23 for grinder is possible. Designate a value between 22, 23 in general.

Tool Information

Machining Center

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

0:2034:0:0:9 | Current Tool number | System.Int32 | MachiningCenterV2 | >= 3.0.0 | [X] P200M [O] P300M/S(MP) |

0:2035:0:0:9 | Next Tool number | System.Int32 | MachiningCenterV2 | >= 3.0.0 | [X] P200M [O] P300M/S(MP) |

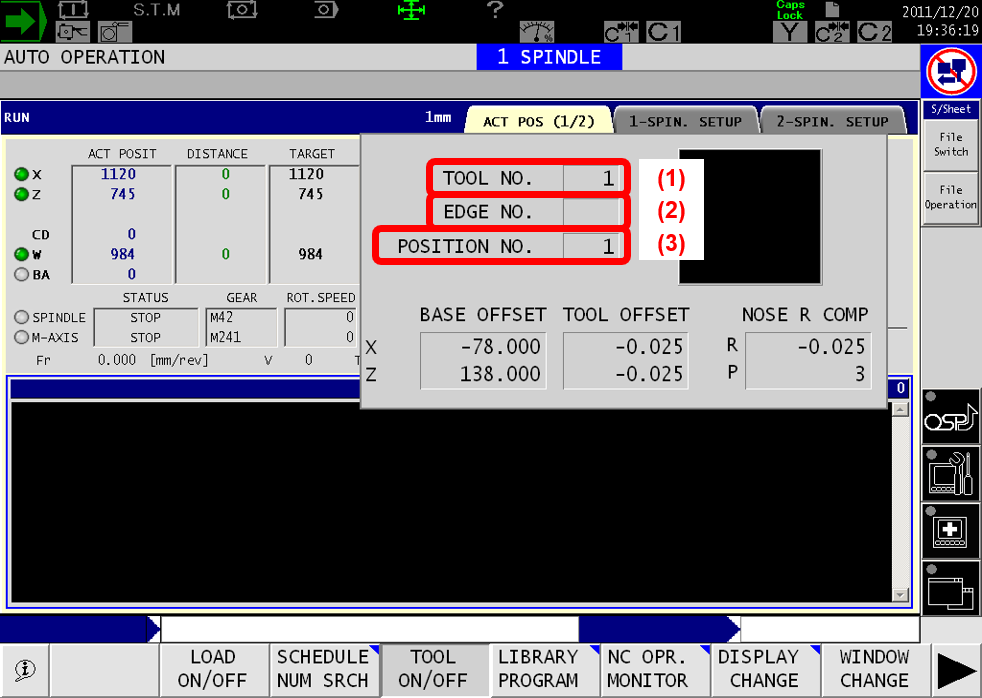

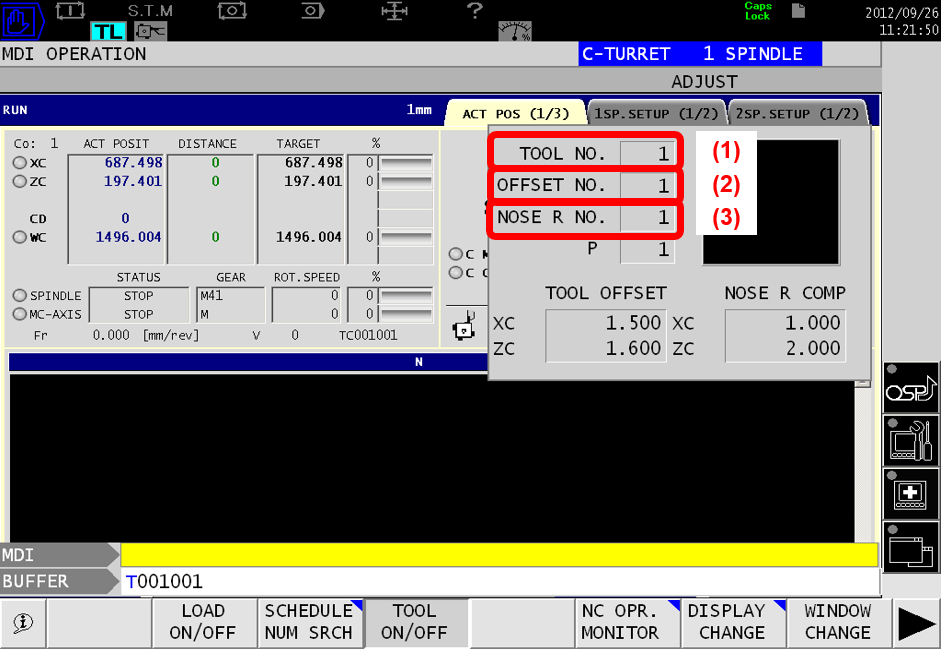

Lathe

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

{SubSystem}:2095:0:0:9 | Get the being indexed tool no. to the current machining position. | System.Int32 | Lathe | >= 1.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:2421:0:0:8 | Get the being indexed turret no. to the current machining position. | System.Int32 | Lathe | >= 3.2.0 | [X] P200L [O] P300L [X] P300S(LP) |

{SubSystem}:2144:0:0:8 | Get the selected offset no. | System.Int32 | Lathe | >= 3.2.0 | [O] P200L [O] P300L [X] P300S(LP) |

{SubSystem}:2145:0:0:8 | Get the selected nose R no. | System.Int32 | Lathe | >= 3.2.0 | [O] P200L [O] P300L [X] P300S(LP) |

{SubSystem}:1598:0:0:8 | Get the being indexed edge no. to the current machining position. | System.Int32 | Lathe | >= 3.0.0 | [X] P200L [X] P300L [O] P300S(LP) |

{SubSystem}:1599:0:0:8 | Get the being indexed position no. to the current machining position. | System.Int32 | Lathe | >= 3.0.0 | [X] P200L [X] P300L [O] P300S(LP) |

SubSystem: Designating SubSystem = 0, 5 to 7, 19 to 29 for lathe is possible. Designate a value between 22 to 26, 28, 29 in general.

Fig: Tool Information P300S(LP)

Fig: Tool Information P300S(LP)

Fig: Tool Information P200L and P300L

Fig: Tool Information P200L and P300L

Spindle Information

Machining Center

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

0:2006:0:0:8 | Get the command spindle revolution per minute (rpm). | System.Int32 | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

0:2007:0:0:8 | Get the actual spindle revolutions per minute (rpm). | System.Int32 | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

0:2014:0:0:8 | Get the spindle load (%) | System.Int32 | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

0:2016:0:0:8 | Spindle Override in % | System.Int32 | MachiningCenter | >= 2.3.0 | [O] P200M [O] P300M/S(MP) |

Lathe

| Address | Description | Data Type | MachineType | Version | OSP Adapt. |

|---|---|---|---|---|---|

{SubSystem}:3053:0:0:8 | Get the spindle speed(RPM). | System.Int32 | Lathe | >= 2.0.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:2038:0:0:8 | Get the spindle load value(%). | System.Int32 | Lathe | >= 2.4.0 | [O] P200L [O] P300L [O] P300S(LP) |

{SubSystem}:2040:0:0:8 | Get the second spindle load value(%). | System.Int32 | Lathe | >= 2.5.0 | [O] P200L [O] P300L [O] P300S(LP) |

SubSystem: Designating SubSystem = 0, 5 to 7, 19 to 29 for lathe is possible. Designate a value between 22 to 26, 28, 29 in general.

Grinder

| Address | Description | Data Type | MachineType | Version |

|---|---|---|---|---|

{SubSystem}:2943:0:0:8 | Get the state of spindle override switch (%). | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:2948:0:0:23 | Get the spindle load value(%). | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:2006:0:0:8 | Get the spindle speed(RPM). | System.Int32 | Grinder | >= 3.0.0 |

{SubSystem}:2924:0:0:8 | Get the wheel spindle speed(RPM). | System.Int32 | Grinder | >= 3.0.0 |

SubSystem: Designating SubSystem = 0, 5, 19, 20, 22, 23 for grinder is possible. Designate a value between 22, 23 in general.